Based in Faber, Virginia, Gremlin Works LLC excels in manufacturing low- to medium-volume production runs of specialized, high-precision parts. Our machine shop is co-owned and founded by engineers from the University of Virginia with degrees in mechanical and systems engineering.

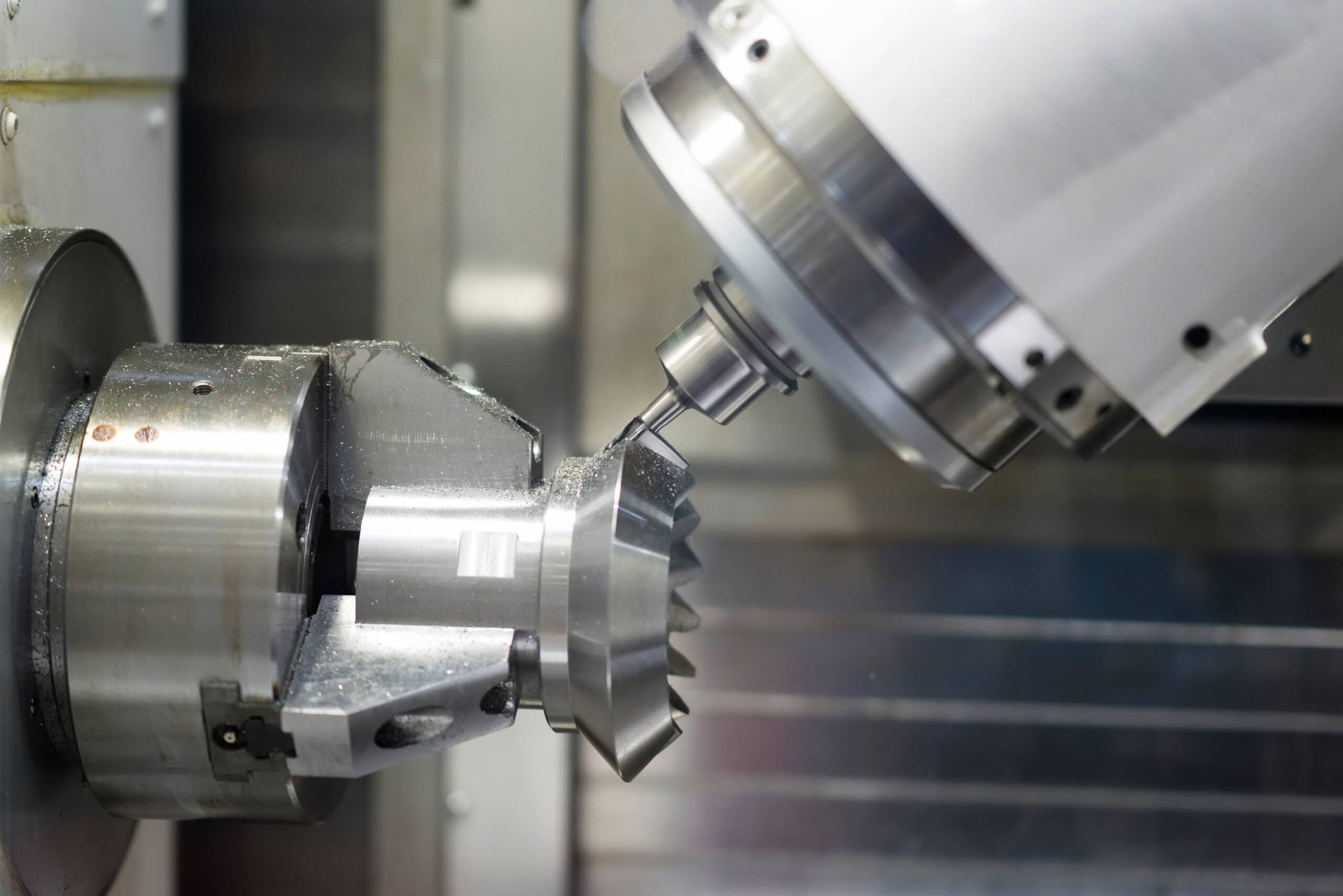

Our growing team of engineers, machinists, and programmers specializes in precision CNC machining, with team members skilled in both prototyping and production processes to handle diverse projects. Our background in product design and development also allows us to offer design feedback and suggestions to optimize products for manufacturability and, where possible, drive out inefficiencies and costs.

When you choose Gremlin Works for your machining needs, you’ll have the peace of mind that your manufacturing partner has the technical know-how and equipment to best assist you. From our facility near Charlottesville, Virginia, we serve local, national, and global companies using advanced multi-axis subtractive manufacturing and quality inspection equipment. Our capabilities encompass parts large and small, designs simple and complex, along with a broad spectrum of material options.

We have multi-industry expertise, working with clients in demanding industries like aerospace and defense, healthcare and medical research, heavy industry, energy, automotive, and more. Boeing, Honeywell, the U.S. National Laboratories, Abbott Laboratories, St. Jude Medical, BMW, and Tesla are just a few of the well-known organizations for whom Gremlin Works has produced parts. Our company also maintains a DDTC Manufacturer Registration (ITAR) and NIST 800-171 compliance to support our work in the defense sector.

Gremlin Works is committed to quality products and production, competitive turnaround times, exceptional customer service, and continuous improvement. We’re excited to continue our growth in the machining market, helping customers tackle their most challenging projects.

Why Work With Us?

Digital-First Company

At Gremlin Works, we pride ourselves on being at the forefront of manufacturing. By combining our advanced computer-aided manufacturing (CAM) and work management software with customer-supplied 3D models, our digital-first company provides streamlined manufacturing services for precision products. Gremlin Works also has in-house computer-aided design (CAD) capabilities, allowing us to build custom workholding solutions for even the most complicated projects.

Competitive Lead Times and Expedited Service

Gremlin Works understands that even the highest-quality product isn’t worth much if you don’t receive it when you need it. That’s why we prioritize efficiency in our operations, enabling us to offer below-average lead times in our market. Also, for clients who require expedited service due to unforeseen circumstances or tight deadlines, we’re here to help. Whenever possible, we’ll work to accommodate your scheduling requirements.

Collaborative and Results-Driven Approach

Our team believes in taking a collaborative and results-driven approach to prototyping and production. We’ll work closely with you to understand your vision, supporting you through the product development and manufacturing processes. We’re also happy to coordinate with an outside service provider if there’s someone you typically work with on product assembly, metal treatment, or finishing. Whatever your project needs, be they simple or complex, we offer the engineering and machining expertise, competitive turntimes, and operational flexibility to deliver results.

Our Team

Miller Garrett

Co-owner

Nicholas Anselmo

Co-owner